Sleeve Boxes Products

Sleeve boxes show a new approach to packaging design that changes the simple act of opening a package into an engaging customer experience. These fascinating boxes feature a unique slide-out effect that creates anticipation and excitement as the outer sleeve gracefully reveals the inner contents. The unique two-part construction consists of an outer sleeve that slides smoothly over an inner tray, creating an unmatchable unboxing experience that instantly communicates quality and attention to detail to clients. The manufacturing precision required for sleeve boxes ensures seamless operation while maintaining structural integrity throughout repeated use. This crafting excellence creates packaging boxes that not only protects products efficiently. But also serves as a marketing tool that enhances brand image and customer satisfaction.

Building Excellence with Custom Sleeve Boxes

The foundation of exceptional packaging begins with custom sleeve boxes that transform standard boxes into personalized brand ambassadors. The customization process involves carefully selecting materials, colors, printing techniques, and structural modifications that align perfectly with brand identity and product requirements. This comprehensive approach to personalization ensures that every element of the packaging contributes to brand recognition. While delivering functional excellence that protects products during shipping and handling. Custom sleeve boxes accommodate complex branding requirements through design processes that incorporate logos, graphics, typography, and color schemes into cohesive brand experiences. The large surface area provided by the sleeve design offers ample space for creative expression, product information, and marketing messages that engage customers.

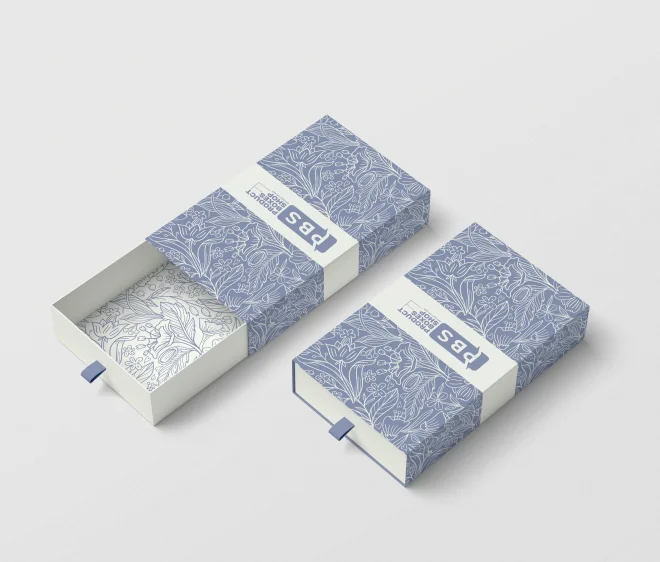

Perfecting Functionality with Tray and Sleeve Boxes

The evolution from basic customization advances to tray and sleeve boxes that represent the pinnacle of functional elegance in packaging design. This appealing configuration features a sturdy inner tray that securely holds products while the outer sleeve provides protection and branding opportunities. The precise crafting required to create smooth sliding action between components demands exceptional manufacturing tolerances and quality control measures. The tray and sleeve configuration offers superior product organization compared to single-component alternatives while providing multiple surfaces for branding and information display. The inner tray can incorporate custom compartments, dividers, or cushioning elements that secure products perfectly, while the outer sleeve serves as a canvas for impactful graphics and messaging.

Embracing Sustainability with Kraft Sleeve Boxes

As environmental consciousness becomes increasingly important to consumers and businesses, kraft sleeve boxes provide an eco-friendly packaging solution without compromising quality or presentation value. The natural kraft material offers a distinctive aesthetic that appeals to environmentally conscious customers while maintaining the structural strength necessary for reliable product protection. The organic appearance of kraft materials creates unique branding opportunities that emphasize authenticity and environmental responsibility. For Kraft sleeve boxes we utilize recycled and recyclable materials that support circular economy principles. While delivering packaging performance that meets demanding commercial requirements. The natural texture and color variations inherent in kraft materials add visual interest and tactile appeal that enhances the overall unboxing experience.

Advancing to Premium Rigid Sleeve Boxes

Building upon sustainable foundations, rigid sleeve boxes combine environmental consciousness with premium construction quality that delivers exceptional durability and substantial feel. For these boxes we utilize thick, high-density material that provide superior structural integrity. As well as creating packaging that communicates value and quality to customers.

The rigid construction ensures that packaging maintains its shape and appearance throughout shipping, handling, and storage, protecting both products and brand image effectively.The manufacturing challenges associated with rigid sleeve boxes require sophisticated production techniques that maintain smooth sliding action despite increased material thickness and weight.

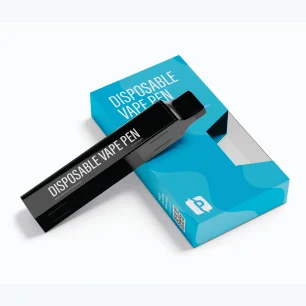

Maximizing Visual Impact with Printed Sleeve Boxes

The progression from premium construction leads to printed sleeve boxes that transform functional boxes into powerful marketing tools through advanced graphic applications. You can use these boxes for different marketing sectors like cosmetics and many more. Modern printing technologies enable full-color graphics, photographic images, and complex designs that create immediate visual impact and emotional connection with customers. The expansive surface area provided by sleeve packaging offers exceptional opportunities for creative expression and comprehensive brand storytelling. Printed sleeve boxes accommodate various printing techniques including offset printing for large runs, digital printing for smaller quantities, and specialty applications such as foil stamping, embossing, and spot UV coating.

Versatile Solutions Through Cardboard Sleeve Packaging

The evolution of printed designs naturally extends to cardboard sleeve packaging that offers optimal balance between cost-effectiveness, functionality, and customization flexibility. Cardboard materials provide excellent printability while maintaining structural integrity necessary for reliable packaging performance across diverse shipping conditions. The lightweight nature of cardboard construction reduces shipping costs while delivering the premium unboxing experience that customers associate with quality brands. Cardboard sleeve packaging accommodates various thickness options and corrugation styles that can be optimized for specific product requirements and shipping environments.

Create Memorable Gift Experiences WIth Product Boxes Shop

The inherent elegance and functionality of PBS sleeve boxes make them exceptionally well-suited for gift packaging applications where presentation quality becomes a crucial component of the overall experience. The distinctive slide-out effect creates moments of anticipation and excitement that enhance gift-giving experiences for both presenters and recipients. The sophisticated opening mechanism communicates thoughtfulness and attention to detail that reflects positively on the gift-giver's consideration while creating lasting memories. Gift applications often require custom inserts that secure items perfectly while creating organized presentations that reveal products systematically as the sleeve is removed. This choreographed unveiling process transforms gift opening into memorable experiences that recipients associate with quality and care.

Optimizing Performance with Custom Boxes

We at PBS offer different types of boxes like paper sleeves. But to make them secure for the product the culmination of sleeve box evolution involves incorporating custom inserts that transform basic containers into precision-engineered product presentation systems. These inserts can be manufactured from various materials including die-cut foam, molded pulp, thermoformed plastics, or corrugated cardboard, depending on product requirements and brand positioning strategies. The insert design process considers product dimensions, fragility levels, presentation angles, and removal convenience to create optimal customer experiences that showcase products effectively.

Frequently Asked Questions

Sleeve Boxes are a type of packaging made up of two main parts — a sliding outer sleeve and an inner tray that holds the product securely. Unlike standard tuck or mailer boxes, sleeve packaging provides a premium unboxing experience and better product display. The sleeve serves as an additional branding surface, ideal for retail, gift, and cosmetic packaging, giving products a modern, elegant look while ensuring protection.

Custom Sleeve Boxes are typically made from durable cardboard, kraft paper, or rigid board, depending on the product’s weight and desired look. For sustainable options, kraft sleeve boxes are popular due to their recyclable nature. Premium versions may use rigid board for luxury presentation, while folding carton sleeves offer a more lightweight and economical option for everyday retail packaging.

Sleeve Boxes offer exceptional customization flexibility. Businesses can print full-color artwork, add logos, foil stamping, embossing, or matte/gloss lamination for a high-end finish. The outer sleeve can feature a die-cut window for product visibility, while the inner tray can be tailored with inserts or compartments for product organization. This versatility makes custom sleeve packaging ideal for cosmetics, electronics, food, and apparel products.

Yes, many Sleeve Boxes are made from eco-friendly and recyclable materials like kraft board and paperboard. Because of their two-piece design, they can be reused multiple times for storage or gift wrapping. Choosing kraft sleeve packaging or using soy-based inks further enhances sustainability, making them a perfect choice for brands focusing on eco-conscious packaging solutions.